Rock Stress Monitoring

“Monitoring of rock stresses is a key issue for ensuring the overall safety of the mining crew and avoiding damage to machines due to rockburst and roof falls.”

– Piotr Mertuszka, KGHM Cuprum

Piotr Mertuszka is a Deputy Manager of the Rock Engineering Department, employed as an assistant professor, specialized in numerical modelling and blasting in underground mines. He is also a lecturer in the Mining Institute at the Wroclaw University of Science and Technology, where he received a PhD degree in 2016. His background is rock mechanics and numerical modelling as well as blasting technology. Since 2017 he is a licensed expert of the State Mining Authority for mining plant maintenance, formally authorized for testing of explosives for civil use.

We are going to develop and demonstrate in selected panels of Polish copper mines an innovative real-time underground monitoring system of rock mass behaviour before and after the stress release blasting. Such a system will be equipped with high-accuracy sensors and will allow for continuous long-time observations of stress/deformation state. Our intention is to improve work safety and ensure appropriate working conditions aiming to maintain an efficient and uninterrupted technological process.

Why is this matters

Monitoring of rock stresses is a key issue for ensuring the overall safety of the mining crew and also to avoid damages of machines due to rockburst and roof falls. The in-situ observations will help us to understand the mechanism of stress release blasting and will also provide the basis for the development of new criteria concerning changes in geomechanical risk levels. This may in turn improve the efficiency of the blasting operations in terms of safety improvement as well as maintenance of high effectiveness of mining operations.

How we work

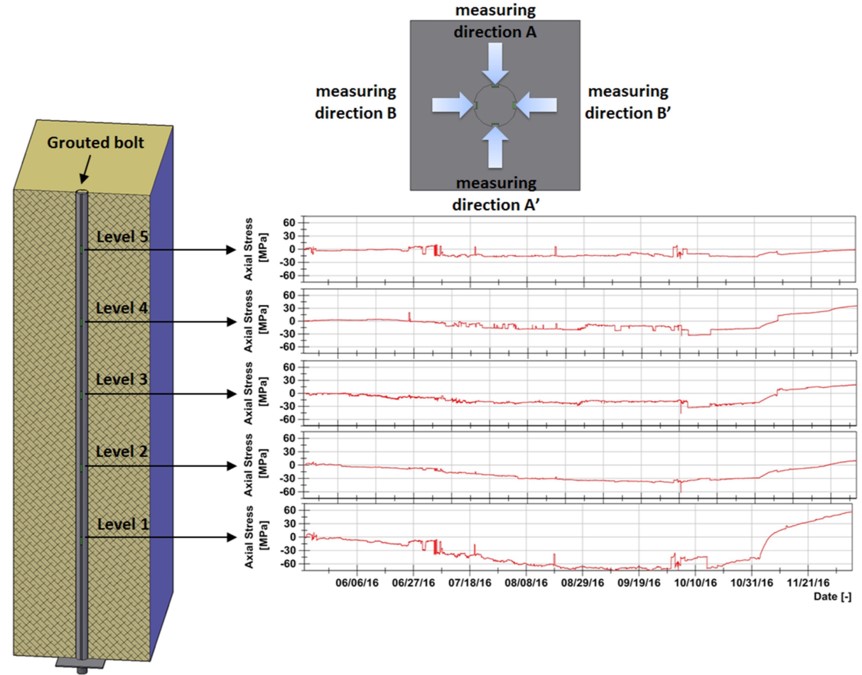

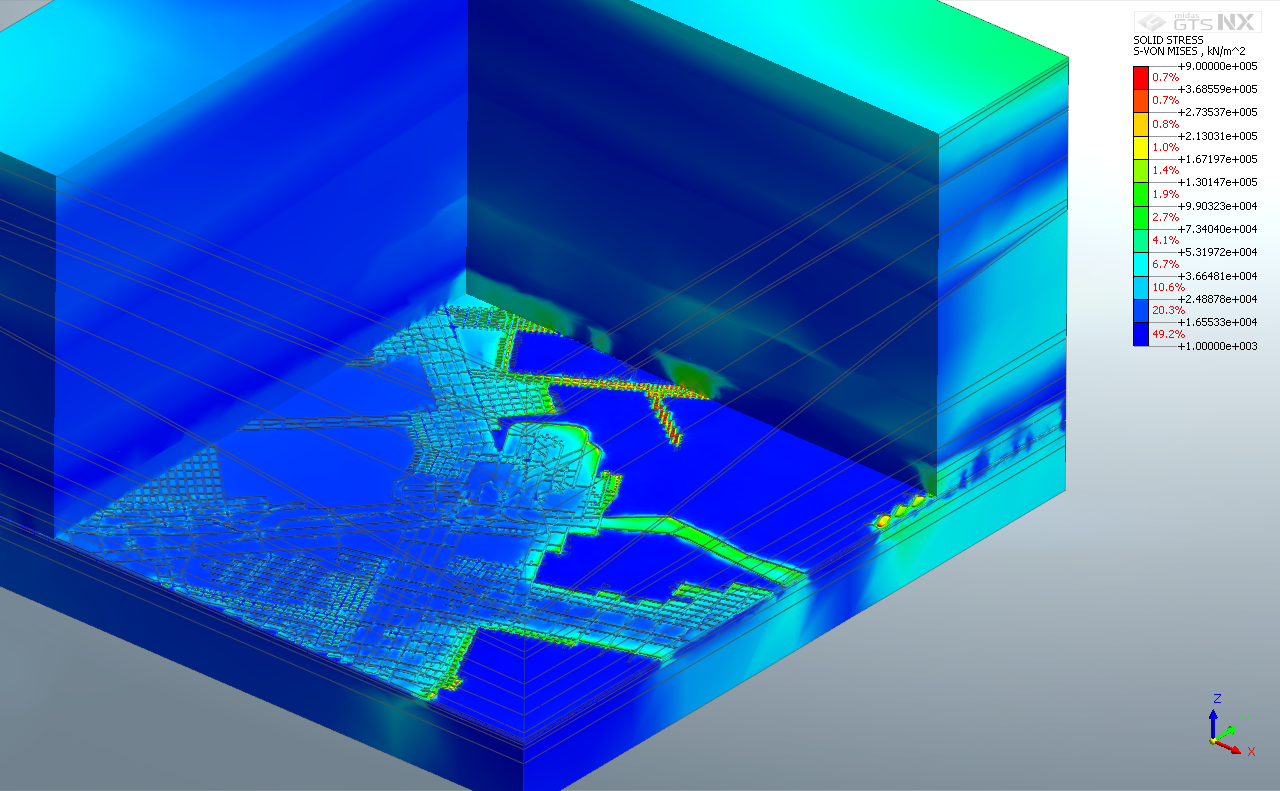

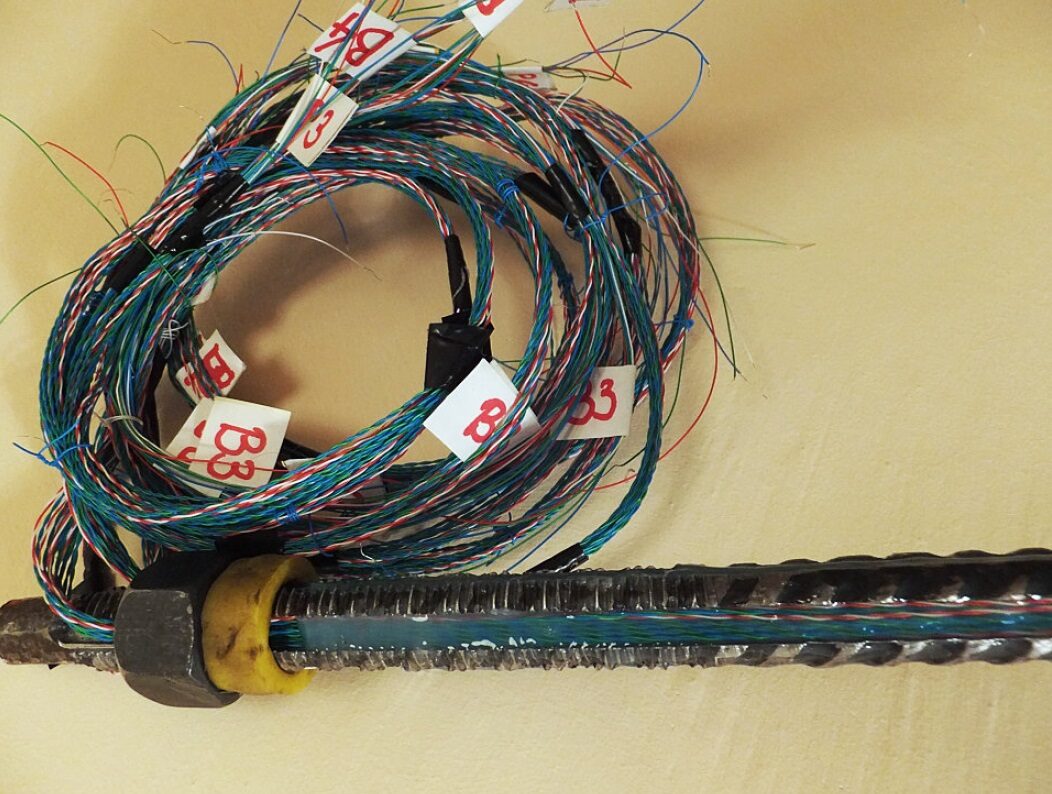

This will be done using the continuous monitoring of geomechanical state of the rock mass based on instrumented rock bolts installed within the roof stratum and sidewalls. Data collected from each device will automatically sent to a real-time integration system. Then, using the seismic records, local changes of seismic wave velocity may be determined and mapped. Comparison of P-wave velocity and stresses around mining panel will allow to assess if destress blasting was effective or not. This approach is completely different than currently practiced, which relies on the occurrence of the seismic events only.

Our challenges

The biggest challenge is ensuring the reliability of the system, which is really challenging in difficult mining conditions, which may be described by very high rock mass and air temperature and extremely high humidity. The other important issue is the integration of all collected data, assessment of the current rock mass state, and finally development of appropriate drilling and firing patterns that will enable amplification of the seismic effect of blasting.

Our goals

Our goal is to improve the effectiveness of intentionally inducing high energy seismic events practiced with the absence of the crew, from presently being achieved level 20–30% by 80%.

Deflection of the roof in room-and-pillar mining

Instrumented rock bolt